18933370499

Contact: Mr. Xu

Mobile phone: 18933370499

Tel: 400-0757-678

E-mail: fuleitejd@163.com

Web site: www.puflt.com

Address: No. 34 Tongji west road, Hongjian industrial park, Shenghui north industrial zone, Nantou town, Zhongshan city, Guangdong province

Website:en.puflt.com

Maintenance and upkeep of polyurethane high-pressure foaming machine gun head:

1. Keep the gun head clean and clean the foam residue on the gun head daily;

2. Regularly add DOP to the gun head for cleaning and lubrication;

3. Ensure that the interior of the gun head is clean. When the foaming machine equipment is stopped, the mixing head should be cleaned with water according to regulations, and the flexibility and reliability of the action should be checked by repeatedly operating the corresponding switch on the operating platform several times.

Cleaning and maintenance of foam machine filter:

The pressure of the raw material tank requires dry air and pressurized with nitrogen gas. Before starting the machine every day, rotate the rotary table of the raw material filter a few turns to the left or right, and once a week, remove 200-300ml of raw material residue from the bottom outlet of the raw material filter. Regularly remove the filter and clean the internal filter pieces with dichloromethane and copper brush, then use DOP to clean the dichloromethane left on the filter pieces for installation and use.

Maintenance and upkeep of the foaming machine chiller:

The chiller regularly inspects the water level in the cold water tank. If the water level drops, it is necessary to add water in a timely manner, replace the water in the tank every three months, and clean the inside of the tank.

Other maintenance items for polyurethane foaming machine:

1. When the equipment is not in use, it should be placed in a cool and ventilated place, and should never be exposed to sunlight. Keep the surface of the equipment clean and free of oil stains, especially the electrical cabinet panels and instrument panels.

2. After 12 months of use of the new equipment, replace the hydraulic oil once. While changing the oil, clean the internal debris of the oil tank, and determine whether to replace the hydraulic oil based on the cleanliness of the hydraulic oil.

3. Regularly check for any loose connections in various oil circuits and feed pump joints.

4. Regularly replace the O-ring inside the gun head, and replace the sealing ring of the material pump shaft according to the actual situation.

5. If the machine is stopped from use, there is no special requirement for a short period of about 7 days.

6. Stop using the equipment for 10-20 days in the mid-term, and start the equipment for 3-5 minutes every 10-20 days to allow high-pressure circulation of raw materials.

7. Long term shutdown requires thorough cleaning of the black material system with DOP.

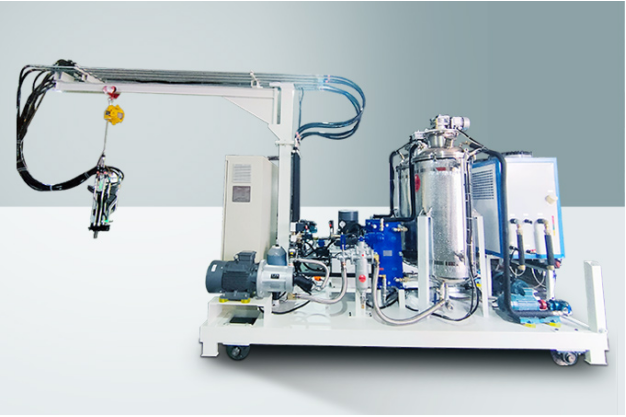

Fuleite's complete set of customized polyurethane foaming equipment includes polyurethane high-pressure foaming machine, polyurethane low-pressure foaming machine, cyclopentane foaming machine, foaming production line, foaming mold, etc.

Fuleite Mechanical and Electrical Technology Co., Ltd.

Mobile phone: 18933370499

E-mail: fuleitejd@163.com

Web site: www.puflt.com

Add: Hongjian Industrial Park, Shenghui North Industrial Zone, Nantou Town, Zhongshan City, Guangdong Province. 34 Tongji west road