18933370499

Contact: Mr. Xu

Mobile phone: 18933370499

Tel: 400-0757-678

E-mail: fuleitejd@163.com

Web site: www.puflt.com

Address: No. 34 Tongji west road, Hongjian industrial park, Shenghui north industrial zone, Nantou town, Zhongshan city, Guangdong province

Website:en.puflt.com

1. At present, a large number of polyurethane soft foam (sponges) are prone to yellowing, so the so-called yellowing resistant foam usually refers to the addition of antioxidants, heat stabilizers and light stabilizers during foaming production, which can temporarily ease the yellowing speed of foam; The main reason for yellowing is that the benzene ring on the isocyanate can be gradually oxidized into a quinone structure and become yellow. In addition, the macromolecular chain of foam contains carbonyl, amino, azo, alkenyl and other chromogenic groups. When light enters, it will be selectively absorbed and emit light of a fixed wavelength, resulting in yellowing of a certain degree of soft foam.

2. An effective solution to yellow change

Among them, the most effective method is to use aliphatic isocyanates that do not turn yellow for foaming. Aliphatic isocyanates, such as IPDI, HDI and HMDI, form stable urethane bonds. To say the least, even if they are decomposed into aliphatic amines, they do not have a benzene ring conjugated structure and will not form a color group, and the aliphatic amines themselves are not easy to be oxidized, which is not easy to cause yellowing; Therefore, the selection of aliphatic isocyanate can significantly reduce the yellowing of foam.

3. Technical difficulties in foaming aliphatic isocyanate

In fact, many people have tried to produce this kind of foam for many years, but most of them have more or less encountered some technical problems, that is, the activity of aliphatic isocyanates is generally low, the foaming process is difficult to control, the operating range or tolerance is very narrow, it is difficult to make soft foam that meets the requirements, and the problems often encountered in the foaming process are: foam collapse or partial foam collapse, coarse foam The surface is powdery or will close the pores, and the lump bubble shrinks more seriously.

It should be noted here that the foam foam made of aliphatic isocyanate will not turn yellow at all, but will also turn yellow by oxidation very slowly under long-term light, water and heat conditions. However, the yellowing speed of this kind of foam is very low, which seems to give people the impression that it does not turn yellow.

4. Main raw materials and additives

(1) , Polyols:

Polyether polyol polyether 210220560s, etc

Highly active polyether polyol, molecular weight 4500-6000, such as 330N, 4701, etc.

Small molecule polyol ethylene glycol, propylene glycol, butanediol, DEG, DPG,

(2) HDI, IPDI and HMDI are commonly used as isocyanates,

(3) , catalysts, mainly two types of catalysts, one is organic amine, which has foaming type and gel type, and can be used mainly: triethylenediamine, pentamethyldiethylenetriamine, pentamethyldiphenyltriamine, triethylamine, diazabicyclo (2,2,2) octane, dimethylcyclohexylamine, 2,4,6-tris (dimethylaminomethyl) phenol, etc; Metal catalysts mainly include stannous octanoate, organic bismuth, organic zirconium, organic titanium, and organic cobalt.

(4) , surfactant, mainly including high activity and medium activity, such as L-580, B-8123, B-8002, L-6900, DC-4900, DC-5169, B-8681 and Y-10366.

(5) , foaming agent, water and its physical foaming agent

5. Basic formula

High activity polyether polyol 90-100

Polyether 560s 0-10

Small molecule polyol 0-10

IPDI 25-45

Water 1.5-2.5

Silicone oil B 8123 1.0-2.0

Above amine catalyst 0.2-1.5

Metal salt catalyst 0.5-1.75

Opening agent 0.5-3.0 (opening agent for high resilience, such as KF-28)

6. Foaming process

Different people or regions may have different foaming process methods, mainly due to different formulation, catalyst selection and dosage, and different schemes or methods. The methods here are only for reference.

The highly active polyether and other additives shall be mixed uniformly at room temperature in advance, and then poured into IPDI for stirring for 6-15 seconds, and then poured into the pre preheated foaming box. Generally, it is recommended to use an oven at least 30 ℃ for heat preservation and foaming. After 20-30 minutes, the foam shall be pushed out and cured at room temperature for 24 hours before cutting. The bubbles are uniform and delicate, with high strength, good elasticity, no pulverization, and generally do not shrink. It needs to be pressed slightly when it shrinks slightly. It needs to be specially reminded not to use grafted polyether polyols.

7. Differences in reactivity between different aliphatic isocyanates and hydroxyl groups

This is a technical difficulty in the production of aliphatic isocyanate foam foaming. The key technology lies in the selection and adjustment of formula and catalyst, which still has some technical know-how.

8. Yellowing resistance of foam

According to ASTM-D-1148 yellowing resistance test method, the test conditions are: 50 ℃, 300 watt hernia lighting results:

It can be seen from the test results in the table above that the yellowing resistance of aliphatic isocyanate foam is relatively good.

The paper is scraped to uniform thickness continuously, and then cured and shaped by oven constant temperature gel. The product is rolled and then matured; The unique foaming process determines the outstanding performance of the material.

Key points of technology:

The reaction rate should be properly controlled by organometallic salts.

Strict temperature control is also an important factor to control product quality.

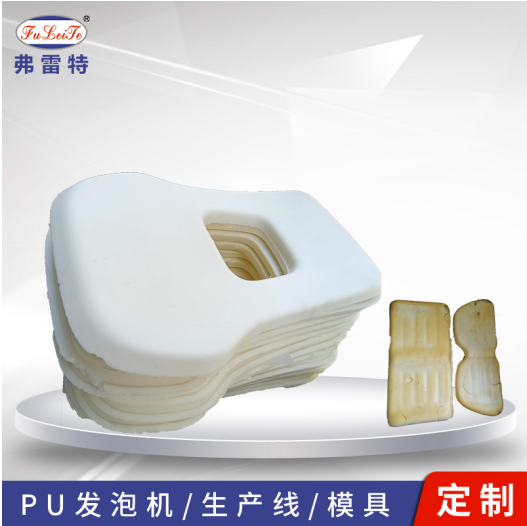

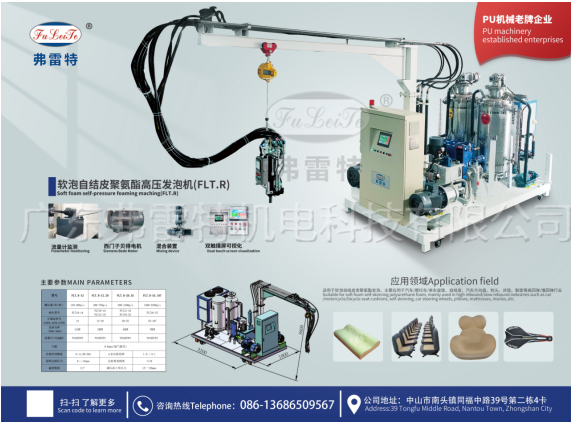

Guangdong Fuleite Electromechanical Technology Co., Ltd., located in the Industrial Zone, No. 39, Tongfu Middle Road, Nantou Town, Zhongshan City, Guangdong Province, is a polyurethane mechanical automation production enterprise integrating R&D, production, sales and after-sales service. Our company specializes in developing and manufacturing various polyurethane foaming machines, cyclopentane foaming machines, automatic foaming production lines (suspension lines/ground rails/disk lines, etc.), automatic foaming mold frames, mechanical arms and other complete sets of polyurethane foaming equipment, helping thousands of polyurethane product production enterprises to achieve "high product excellence rate and low equipment failure rate".

Fuleite Mechanical and Electrical Technology Co., Ltd.

Mobile phone: 18933370499

E-mail: fuleitejd@163.com

Web site: www.puflt.com

Add: Hongjian Industrial Park, Shenghui North Industrial Zone, Nantou Town, Zhongshan City, Guangdong Province. 34 Tongji west road